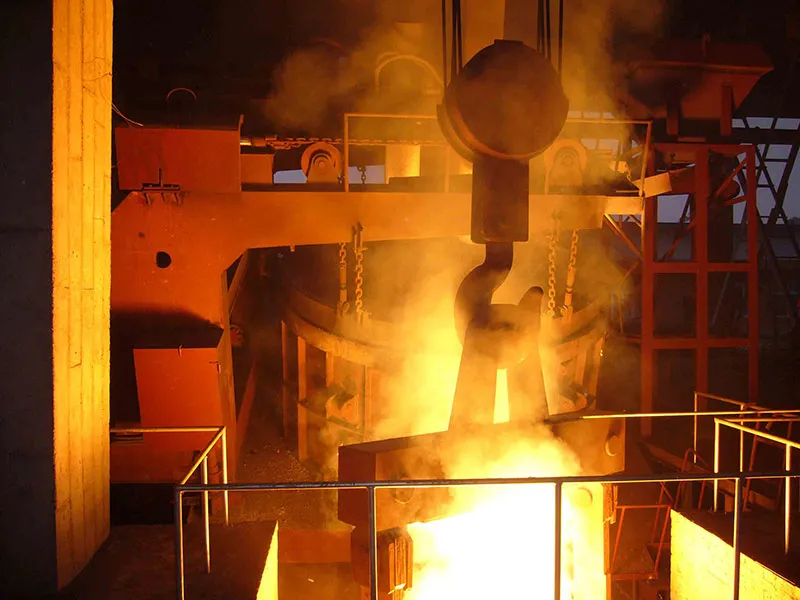

Electric Arc Furnace (EAF)

In the entire smelting process, the electric arc furnace is a preliminary melting scrap furnace that can smelt high-quality carbon structure steel, alloy structure steel, stainless steel, bearing steel, tool steel and other steel types.

The furnace using ultra-high-power, high-impedance and other new technologies, the steel using a steel mouth way. Smelting adopts submerged arc smelting operation process, the process can greatly improve the furnace active power input, reduce the power loss. At the same time configurable carbon and oxygen gun and the furnace wall oxygen burner, can greatly shorten the smelting cycle, reduce power consumption, improve the steel yield.

In terms of smelting metal, the electric arc furnace is much more flexible and effective than any other steel-refining furnaces in that it can well remove impurities, such as sulfur, phosphorus, etc. and take up less floor space. And its temperature is easy to control. Furthermore, taking the electric energy as the heat source, the electric arc furnace is incredibly ideal for smelting of the steel types containing elements subject to oxidation by adjusting the atmosphere inside.

Shanghai Electrical Machinery

Shanghai Electrical Machinery