Hydropower Station

In hydropower station applications, SEMC motors mainly offered the following options:

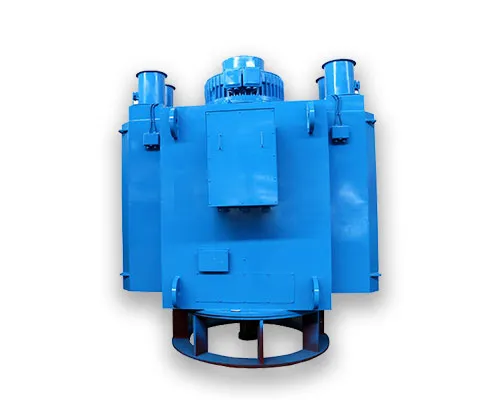

- VHS motors are used for water extraction to ensure an uninterrupted water supply.

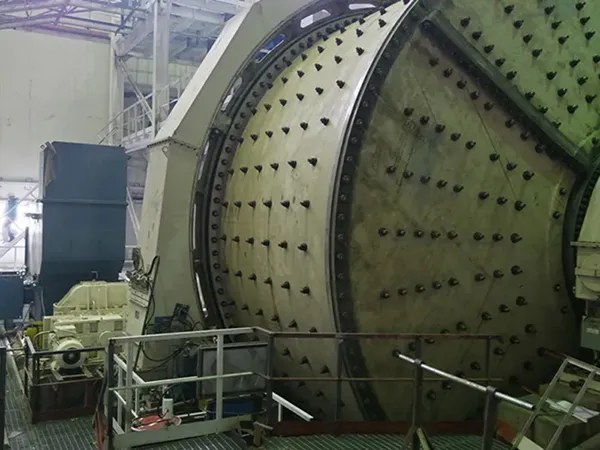

- High voltage motors are used to drive auxiliary high-power equipment within the plant.

Request a Quote

Advantages of SEMC’s Motor on Hydropower Stations

- High-Grade Insulation: SEMC’s motors are designed to operate reliably in the humid environments of hydropower plants. Our motors are equipped with Class H insulation, providing excellent dielectric strength and long-term durability.

- Thermal Monitoring: Our motors are equipped with temperature monitoring modules to prevent overheating and protect internal components.

- Advanced Lubrication Management: We use fully synthetic lubricants that remain effective across extreme temperature ranges from -40°C to 180°C. Regular monitoring and replacement of lubricant ensures optimal motor performance over time.

- Moisture and Dust Protection: Our motors feature sealed or protective housing structures, preventing moisture ingress and safeguarding the internal components against insulation degradation due to environmental exposure.

- Comprehensive Protection Features: Equipped with a built-in protection mechanism against overload, short circuit, undervoltage, and overheating, ensuring safe operation in critical power-generation environments.

These advanced design features make SEMC motors a reliable and cost-effective solution for hydropower facilities, helping to minimize downtime and maintenance costs while supporting long-term grid stability.