Metallurgy & Smelting

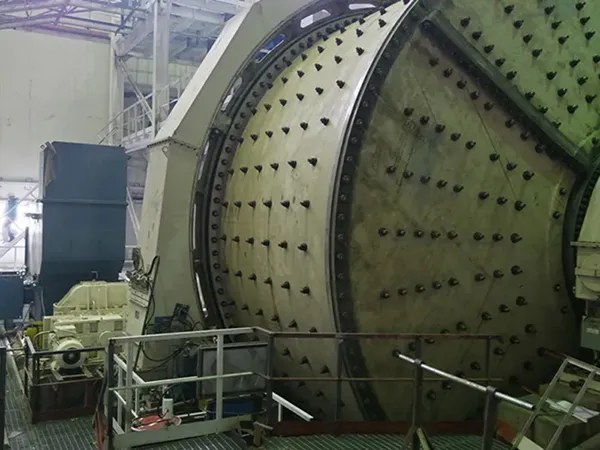

Our high voltage motors and large-sized DC motors are widely used across metallurgy applications, powering essential machines such as steel rolling mills, continuous casting machines, and overhead crane motors in smelting plants. Designed with resilience in mind, our motors are engineered to handle the extreme mechanical and thermal stress, ensuring reliability for heavy-duty operations.

Request a Quote

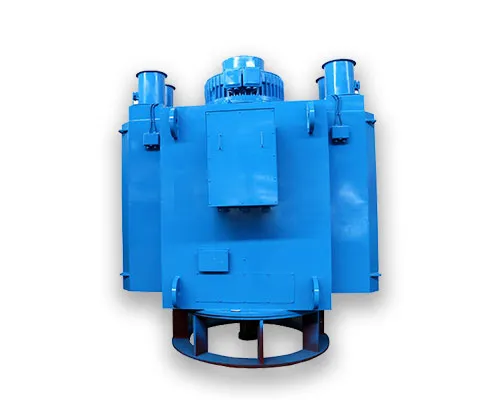

Advantages of SEMC’s VHS Motor for metallurgy and smelting

- Exceptional product quality, with 10 years or more service life under continuous operation. Designed for 24/7 uptime, our motors help reduce downtime and operational costs. Energy efficiency levels reach IE4 and IE5, supporting your sustainability goals without compromising performance.

- Tailored torque output designed for your metallurgy and smelting equipment, maximizing mechanical compatibility and system efficiency for outstanding performance.

- With rich industry experience, we can recommend the most suitable motor models based on your requirements, including: YKK slip ring motor, YRKK slip ring motor, Y Series squirrel cage motor, Z Series DC motor, and ZZJ DC motor.

- All motors use 100% oxygen-free copper windings, ensuring high conductivity, lower energy loss, and greater reliability under high loads.

- Built-in protection system, such as thermistors and bearing temperatures, preventing overheating and ensuring reliable performance.

- Features flexible cooling system options from air-to-air (fan-cooling) and water-cooled systems, adjustable to your situations.

- Our motors feature superior thermal performance for low temperature rise and high-grade insulation (up to Class H), ensuring thermal stability during intensive use.