Countries worldwide are making exciting strides towards carbon neutrality and sustainable development. As a result, traditional energy sources like high-emission diesel generators are gradually falling out of sync with today's environmental standards, paving the way for cleaner alternatives.

To tackle the challenge of sustainability, governments and industries worldwide are enthusiastically promoting clean energy solutions like solar, wind, and hydropower. For example, harnessing solar energy to power VHS motor, offering a practical and eco-friendly option for agricultural irrigation. These options operate with nearly zero carbon emissions, serving as an excellent alternative to traditional diesel generators. This approach significantly decreases pollution and greenhouse gas emissions, all while propelling the world’s progress toward environmental goals.

In regions like Saudi Arabia, accessing water can be quite a challenge due to the intense desert climate with its relentless sunlight and dry conditions. That's why we’re excited to share that vertical solid shaft turbine pumps equipped with our VHS motor have proven to be highly reliable and effective in challenging environments. It also shows outstanding carbon neutrality and environmental compliance. Our VHS motor consistently delivers high efficiency, even in extreme heat, ensuring communities can thrive amidst the challenges.

At high altitudes (2,000m to 3,500m) with low precipitation, our VHS motors excel by providing robust torque that empowers deep-well pumps to efficiently extract water from hundreds of meters underground, even beneath rocky layers. This innovation significantly enhances irrigation for crops like wheat and other grains, transforming local agricultural conditions. This improves the crop yields and enhances the local community’s access to food, leading to an improved quality of life for all.

Wide Range Voltage Compatibility

A broad range of 300~460V, our VHS motors can easily adapt to different voltages in different countries worldwide, significantly reducing the risk of power failure or unexpected shutdown.

Standardized Variable Frequency Drive (VFD) Support

Our motors are compatible and equipped with VFD technology.

- Smooth Start-Up: Soft acceleration from 0~1800 RPM, which minimizes impact on the power grid.

- Flexible Operation: Operates efficiently within a VFD operation range of 30–75Hz and can start reliably even from 0Hz.

Premium Bearing

- Sealed Bearing: Effectively keeps sand and debris out to minimize damage to the VHS motor during operations, ensuring your motor performs reliably and lasts for years.

- Trusted Brands: Our standard VHS motors are equipped with TMB, NSK, or SKF bearings for enhanced durability.

High-Temperature Cooling System

Our VHS motors feature innovative thermal management solutions that integrate various cooling methods, including oil cooling (compliant with U.S. NEMA standards), air cooling, and water cooling. This versatile system ensures reliable performance even in desert or high-temperature environments ranging from 50–80°C.

Intelligent Temperature Monitoring

- Each VHS motor is equipped with three PTC thermistors embedded within the copper windings. These sensors provide real-time feedback and automatically shut down the system to prevent burnout if temperatures exceed safe limits (e.g., 125°C).

- Additionally, our motors feature PT100 sensors on both upper and lower bearings to monitor bearing temperatures and provide overload protection.

TEFC/IP55 VHS Motor in the Middle East

TEFC/IP55 VHS Motor in the Middle East

A Middle Eastern customer chose our Totally Enclosed Fan Cooled (TEFC) IP55-rated vertical hollow shaft motor for deep well water pumps used in agricultural irrigation.

IP23 VHS Motor for Desert Operations

IP23 VHS Motor for Desert Operations

Our IP23 VHS motor has been successfully installed in a desert region known for extreme dryness and intense solar exposure.

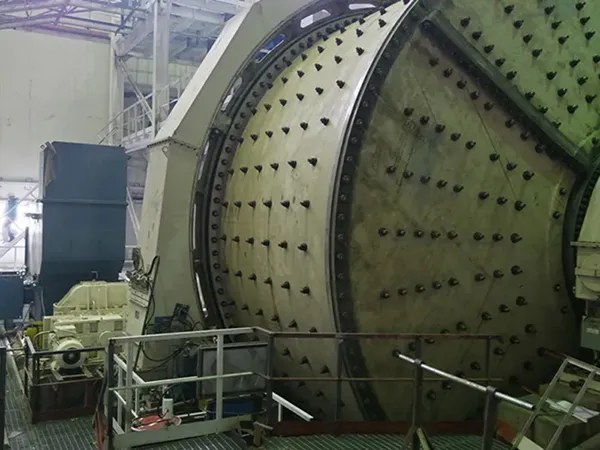

TEFC VHS Motor (NEMA Standard, 350HP, 460V, 60Hz)

TEFC VHS Motor (NEMA Standard, 350HP, 460V, 60Hz)

On-site footage from the customer’s installation site, this video showcases our TEFC Vertical Hollow Shaft (VHS) motor operating in real-time.